- Out-of-Stock

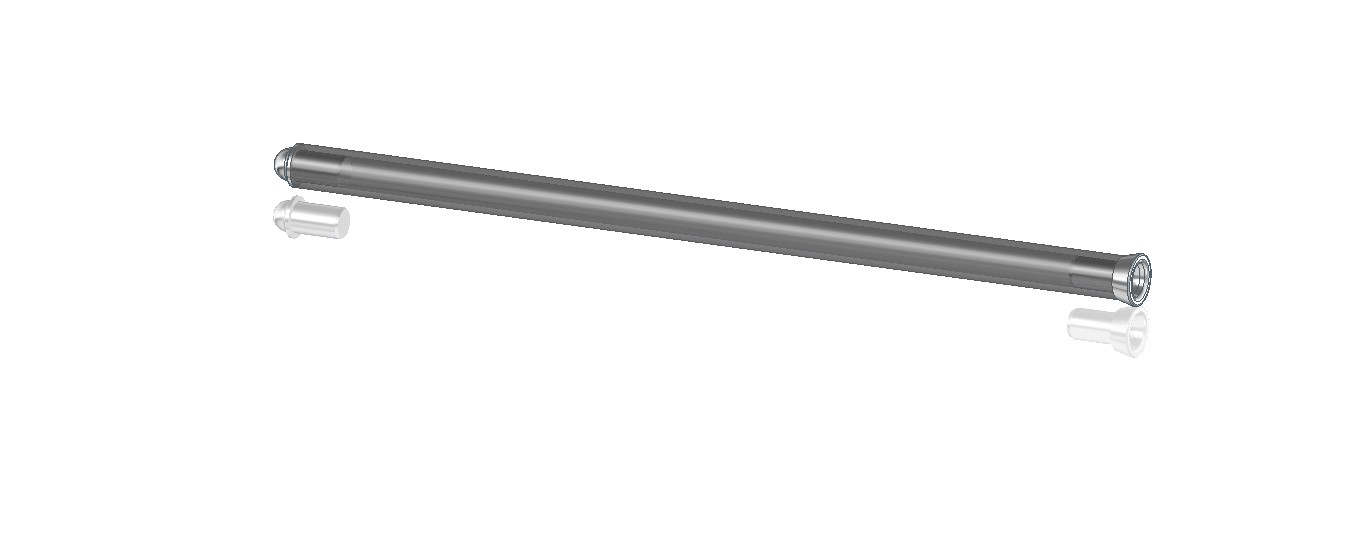

TITANIUM reinforced tubular hollow pushrods (8 units) for Renault 5 Gt Turbo / R11:

Aerospace-grade tubular titanium

Withstand 1500 kg (stock ones only 500 kg)

300% stronger and 500% stiffer than stock pushrods

More valvetrain control: can hold more rpm and realiability

4mm longer (ideal for high-lift camshafts)

Made in SPAIN

Política de seguridad (editar con el módulo Información de seguridad y confianza para el cliente)

Política de envío (editar con el módulo Información de seguridad y confianza para el cliente)

Política de devolución (editar con el módulo Información de seguridad y confianza para el cliente)

The price is for the complete kit consisting of 8 units.

Specs

- Exclusive aerospace-grade titanium material, with certification and full traceability. Titanium extruded from bar stock and 100% CNC machined.

- Withstand forces over 1500 kg (OEM ones only 500 kg).

- 5 times stiffer than OEM. This is critical to ensure valves close properly without bouncing at high RPM.

- Larger outer diameter up to 8mm, increasing stiffness.

- Designed using CAD and Finite Element Analysis (FEA).

- Titanium’s thermal expansion is only 8 × 10⁻⁶ /°C, which is 42% lower compared to stock push rods made from carbon steel (12.5 × 10⁻⁶ /°C). This reduced expansion helps maintain the original valve clearance even in racing applications, ensuring more stable engine performance at any temperature and increasing maintenance intervals.

- CNC-manufactured forged and heat-treated aerospace steel tips, with hardness over 58 HRC, followed by precision grinding and surface treatment.

- VARIABLE wall thickness. To achieve greater strength, lightness, and rigidity, the inner diameter of the tube is machined with different wall thicknesses according to the stress zones.

Why Titanium?

It is the best material for this application. In addition to its high yield strength, hardness, toughness, and lightness, it is completely corrosion-resistant in any environment and much stiffer. Titanium is also the metal with the lowest thermal expansion, making it ideal for the valve train.

The original valve train is designed to operate up to a maximum of 6500 rpm with the stock camshaft.

To improve valve control, reliability, and power, the valve train (retainer, valve, push rod, lifter, rocker arm, and spring) must be as rigid—and ideally as lightweight—as possible.

These reinforced pushrods, with higher stiffness, are essential when upgrading valve springs to reinforced versions, replacing the camshaft with a higher lift/more aggressive profile, or increasing boost or rpm.

Thanks to their higher rigidity, they allow valve operation at higher RPM.

The weight and stiffness of the push rods, as well as the mass of any component in the valve train, limit engine performance. At a certain RPM (around 6400 in this engine), the combined mass of the valve train components can overcome the spring force, causing the valves not to fully close. This leads to a loss of proper cam-following, resulting in impacts between parts and significant fatigue stress—accelerating wear on valves, seats, and more.

Manufactured in Spain. Titanium imported from the UK.